- Home

- Product

- Mucking Loader

- Wheel Belt Mucking Loader

- ZWY-50/15T Wheel Belt Mucking Loader

Product Description

Introduction

The small mucking loader ZWY-50 is a mining equipment for continuous operation. It is mainly used in cave mining operations with narrow spaces, such as metal mines, water diversion roadways, etc. The manufacturer designs this machine with a combination of the functions of collection, transportation and loading of gravel and slag for various projects.

The small wheeled mucking loader is a mining equipment for continuous operations. It is mainly used in cave mining operations with narrow spaces, such as metal mines, water diversion roadways, etc. The manufacturer holds that the machine is designed with the functions of collection, transportation and loading of gravel and slag for various projects. This tire mucking loader can be used to shovel rocks which are picked up by the bucket into its own belt conveyor which unloads the rocks into a dump truck or a mine car or other loading equipment. At the same time, the backhoe digging arm can also be used to pick up rocks within the distance, and the bucket can also be used to clean the working face. It is suitable for roadways with a narrow cross-section of 1.8×1.8m or more. The whole machine is driven by four wheels, and the conveyor frame can be folded back. One 50-type small mucking loader can replace multiple manual workers.

Features

The small wheeled mucking loader is a mining equipment for continuous operation. It is mainly used in cave mining operations with narrow spaces, such as metal mines, water diversion roadways, etc. The manufacturer holds that the machine is designed with the functions of collection, transportation and loading of gravel and slag for various projects. This tire mucking loader can be used to shovel rocks which are picked up by the bucket into its own belt conveyor which unloads the rocks into a dump truck or a mine car from the rear. At the same time, the backhoe digging arm can also be used to pick up rocks within the distance, and the bucket can also be used to clean the working face. It is suitable for roadways with a narrow cross-section of 2.2×2.2 m or more.

This machine adopts electric full-hydraulic transmission, and combines four functions of hydraulic travel, excavation, collection, transportation, and loading in one. It has a compact structure, large propulsion force, and wide pick-up range. It can load rocks across the entire section with no dead angles, and does not need manual assistance to clean the working face; the main action of the machine is controlled by a pilot valve.

This small type mucking loader is suitable for 1.8*1.8m working face, it is driven by four-wheel and can be folded by 1 meter. It is efficient and can replace multiple labors.

Reasonable design and high-quality configuration

1, Working Arm: The material adopts the national standard GB/T700-Q235B, the thickness is 8-30mm, and the tensile strength is 235-345MPa.

2, Bushing: The moving part adopts solid graphite inlaid bearing (high-strength brass bushing) wear-resistant self-lubricating bushing, which has good wear-resistance and long service life.

3, Pin shaft: The material is made of 45# or 40Cr round steel after quenching and tempering HB240~280 treatment, which is wear-resistant and fracture-resistant.

Folding Conveyor

When the working face of the roadway meets the corner, the tail of the conveyor frame of the machine can be folded by 70 cm, which is convenient for turning, hydraulic control, and easy operation.

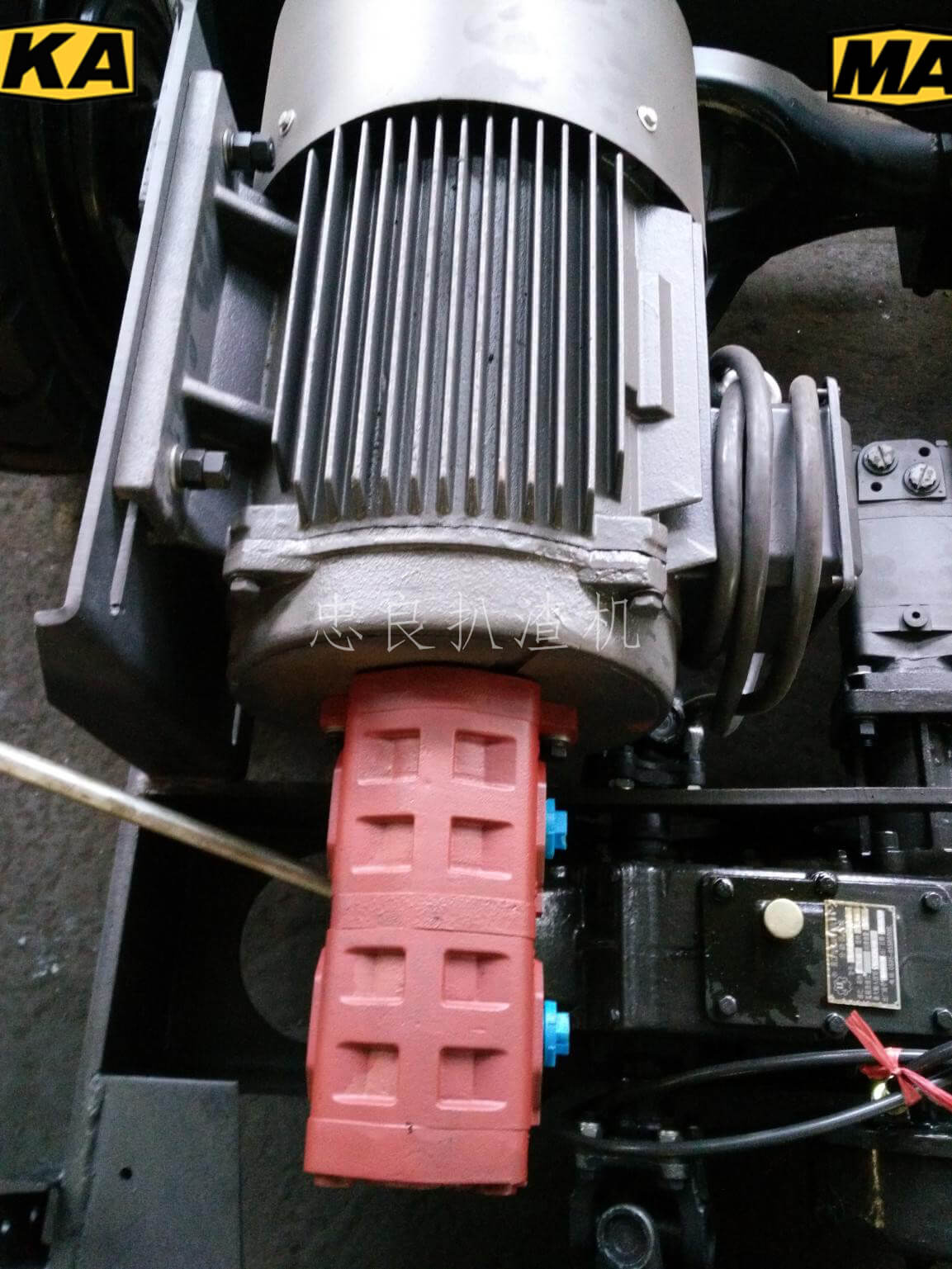

4, Hydraulic Cylinder Oil cylinders are used for the system of this machine, and the thrust of the oil cylinders can reach 49500N. The imported Parker brand seals are used, which have good sealing performance, long life and high reliability.

5, Hydraulic Motor from the BMSY series and BMTZ series for low speed and high torque and the maximum torque can reach 1270Nm.

6, Control Valve produced by Hefei Changyuan Hydraulic Components Factory.

7, Hydraulic Drum The difference with the electric drum is that the conveying part is a hydraulic drum, which is driven by hydraulic pressure and is not affected by the voltage. When the voltage is unstable, the electric drum might burn out the motor due to the lack of box electricity and voltage instability, while the hydraulic drum will not. If the voltage at the mine is insufficient and unstable, you can choose a hydraulic drum.

8, Electrical SystemThe main electrical components are selected from China Chint, and the explosion-proof electrical cables are selected from explosion-proof electric control boxes and flexible cables approved by safety identifications.

Optional

Hammer Breaker

This machine can be equipped with an integrated breaking hammer, which can function for breaking immediately when encountering large stones while removing slag, which is convenient, fast and safe.

The breaker can break stones and clean the floor of the roadway and the bottom of the side wall; it can break large rocks and coal chunks after blasting without supplementary blasting.

There is no need to blast when excavating coal roadways or semi-coal roadways with hardness f≤3.

Cable Reel

Exclusive cable reels are adopted which can realize the flexible and automatic retraction of cables when the equipment enters or exits the site, which saves manpower and material resources, improves safety and automation, and makes the loader enter or exit the site more flexibly. 60 meters can be installed.

Technical Parameter

| Model / Item | ZWY-50/15T0 | |

| Loading Capacity (m³/h) | ≥60 | |

| Digging Distance (mm) | 1300 | |

| Digging Width (mm) | 2400 | |

| Loading Width (mm) | ≥2400 | |

| Digging Height (mm) | 1600 | |

| Digging Depth (mm) | 210 | |

| Unloading Height (mm) | ≥1100 | |

| Ground Clearance (mm) | 180 | |

| Wheelbase (mm) | 1200 | |

| Axle Track (mm) | 1100 | |

| Minimum Turning Radius (m) | ≥5 | |

| Gradeability (°) | ≤8° | |

| Conveyor Belt Speed (m/s) | 0.80±5% | |

| Delivery Capacity (m³/h) | ≥50 | |

| Travelling Speed (m/s) | 0.26±5% | |

| Rated Working Pressure (Mpa) | 12 | |

| Main Motor Power (kW) | 15 | |

| Hydraulic Drum | ||

| Total Power (kW) | 15 | |

| Weight (kg) | 2450±5% | |

| Packaging Size | Length (mm) | 5000/4750 |

| Width (mm) | 1450 | |

| Height (mm) | 1450 | |

| Applicable Roadway Section (m)2 | Above 1.8×1.8m | |

EN

EN  ES

ES RU

RU FR

FR PT

PT العربية

العربية

Tel: +86-0710-3337567

Tel: +86-0710-3337567 WhatsApp: +86-19972252417

WhatsApp: +86-19972252417 Fax: +86-0710-2510617

Fax: +86-0710-2510617

Home

Home Email

Email Product

Product

Welcome to send your message to us