- Home

- Product

- Technology

- Remote Control Management System

Product Description

This remote control system is widely used in mining rock Underground Mining Scaler, mining mucking loader, coal shearer, roadheader, mine loader, excavator, tower crane, fixed hydraulic breaker and other equipment in dangerous areas where the working environment is relatively harsh and poses a threat to personal safety.

Remote Control Management System

System Overview

The remote control management system is a digital intelligent system capable of accurate and real-time collection of on-site information, network transmission, standardized integration, visual display, and intelligent operation. The operator can completely leave the mining operation surface, use the operation console in a safe place beyond the visual distance, and control the mechanical equipment in real time through the network, realizing the less-manned and unmanned production of the entire mining process.

With using this system, the staff can use the operation console to control the mechanical equipment in real time through the Internet of Things network within the scope of network coverage, such as the office on the well or a relatively safe location underground, so as to achieve less-manned and unmanned production.

Explosion-proof Infrared Camera

Remote Operation

Economic and Social Benefits

1, Automated production process: Fewer underground workers save time for going up and down the well, improve production efficiency and reduce expenses.

2, Mining operation safety: Mining personnel will stay away from unsafe and dangerous production environments, which fundamentally solves the problem of safe production.

3, Convenience of personnel recruitment: The change of mining environment will make it easier to recruit young and knowledgeable talents to work, laying a talent foundation for the long-term development of mining enterprises.

Remote Control mucking loader

In recent years, with the advent of the Internet of Things and 5G information age, remote intelligent management technology has emerged as the times require. Aiming at the complex and dangerous working environment under the mine, such as high temperature, dust, landslides, falling rocks, water seepage, gas leakage and other issues have seriously affected the life safety of mining workers. In 2010, Zhongliang Smart Mine Affairs Department was established, and reached cooperation and exchanges with local universities such as Huazhong University of Science and Technology, Chang'an University, Xi'an Jiaotong University, Northwestern Polytechnical University, Hubei University of Arts and Sciences, etc., committed to remote control technology of mining equipment, network communication technology and mine security management technology, etc., to provide customers with tailor-made smart mine solutions.

Achievement:

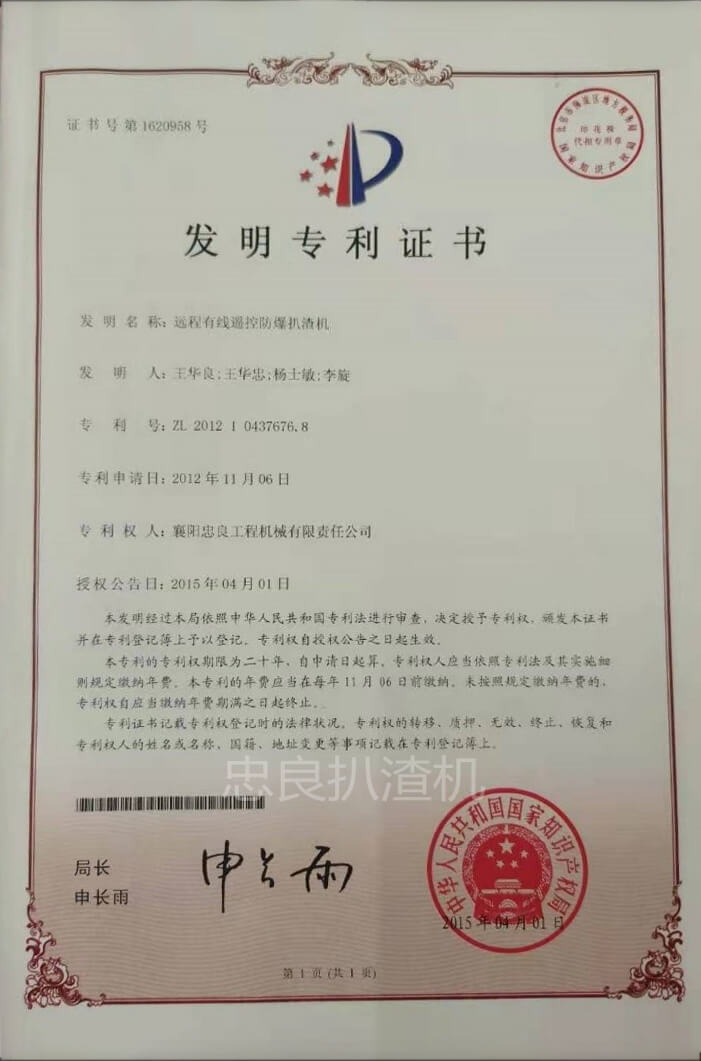

In 2012, the remote control mucking loader; in 2015, the Zhongliang Smart Mine Affairs Department was awarded the certificate of the project.

Certificate for remote control mucking loader

Zhongliang produces remote control continous loader, wheel type remote control mucking loader.

In 2016, the "line-of-sight" remote control system of the company's technical team was modified for mining machinery. The operator carried a wireless remote control with video display and realized various functional actions of the equipment within the range (100 meters) of the mining equipment.

In 2018, the company specially hired an industrial IoT team with a high salary. The team members all have overseas study experience in overseas universities, such as Johns Hopkins University in the United States, the University of South Australia in Australia, and Carnegie Mellon University in the United States. After two years, the "beyond line of sight" remote control system was applied to mine mucking loaders, rock drilling rigs and other vehicle-mounted wireless communication equipment to extend the previous 100-meter remote control distance to the current network control, realizing the effect of remote network control.

EN

EN  ES

ES RU

RU FR

FR PT

PT العربية

العربية

Tel: +86-0710-3337567

Tel: +86-0710-3337567 WhatsApp: +86-19972252417

WhatsApp: +86-19972252417 Fax: +86-0710-2510617

Fax: +86-0710-2510617

Home

Home Email

Email Product

Product

Welcome to send your message to us